ISO 80369 Testing on Small-Bore Connectors for Liquids & Gases in Healthcare Products

Home » Services » Physical and Packaging Testing » ISO 80369 Small-Bore Connectors for Medical Devices

What is a small-bore connector?

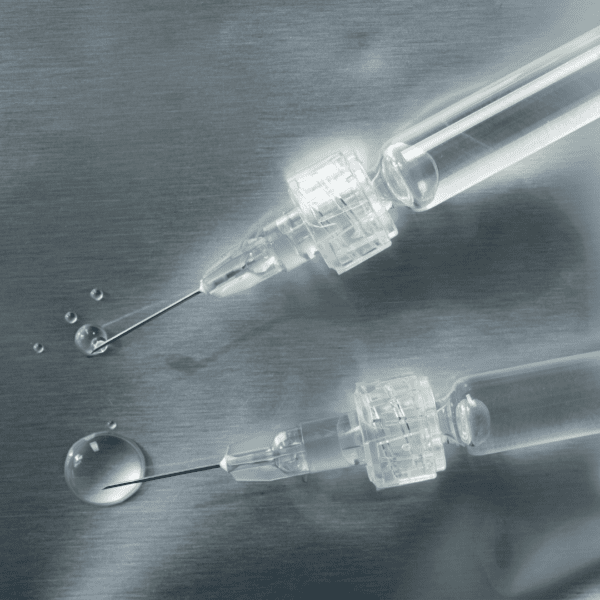

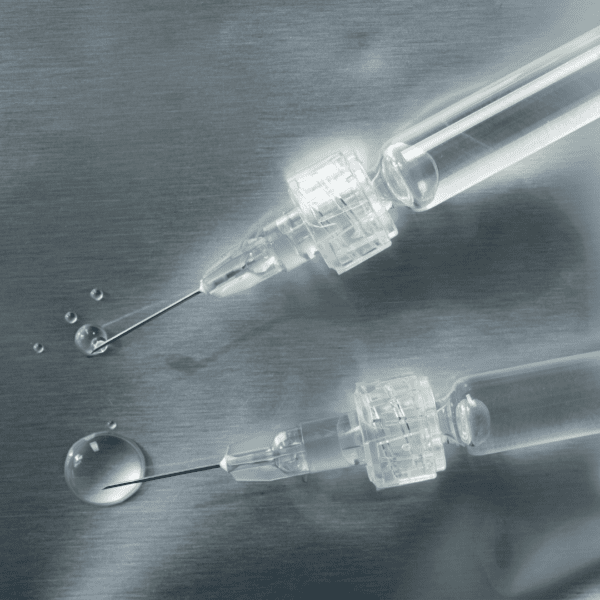

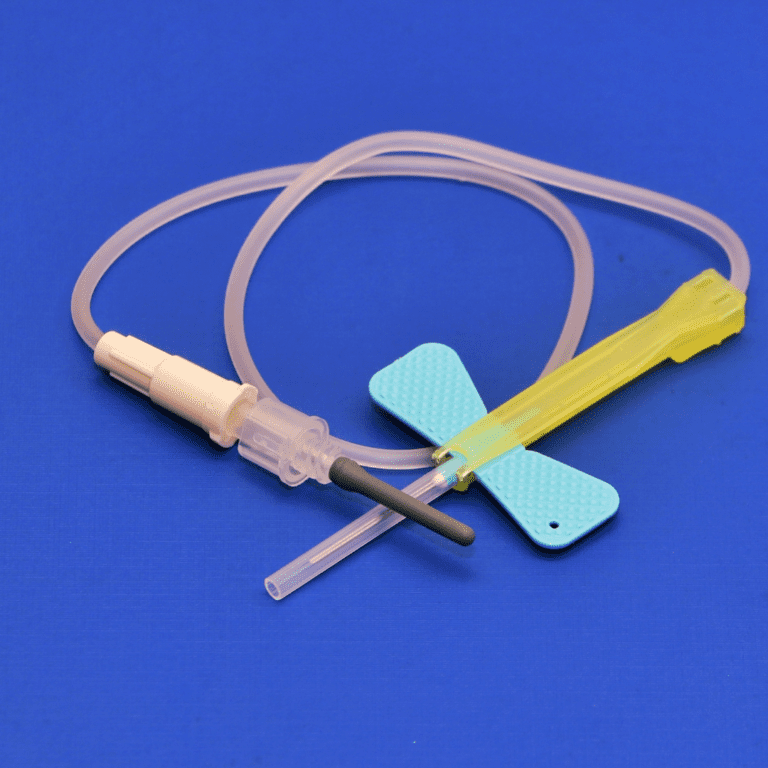

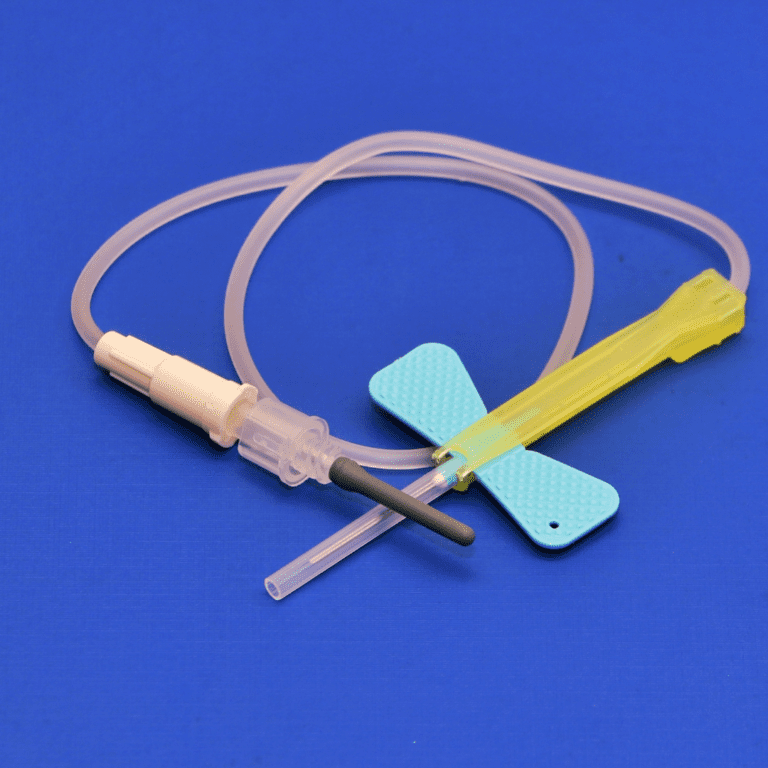

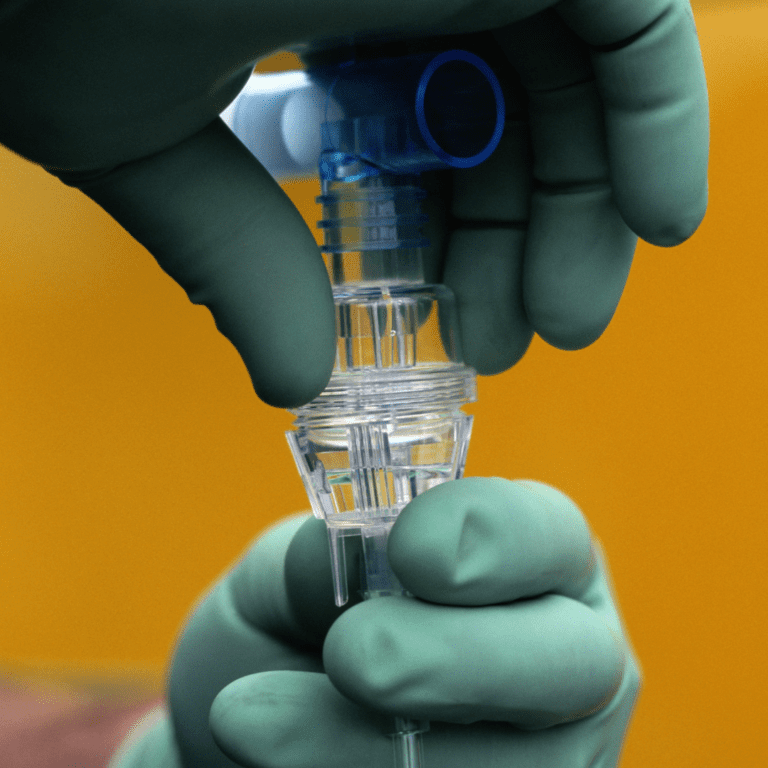

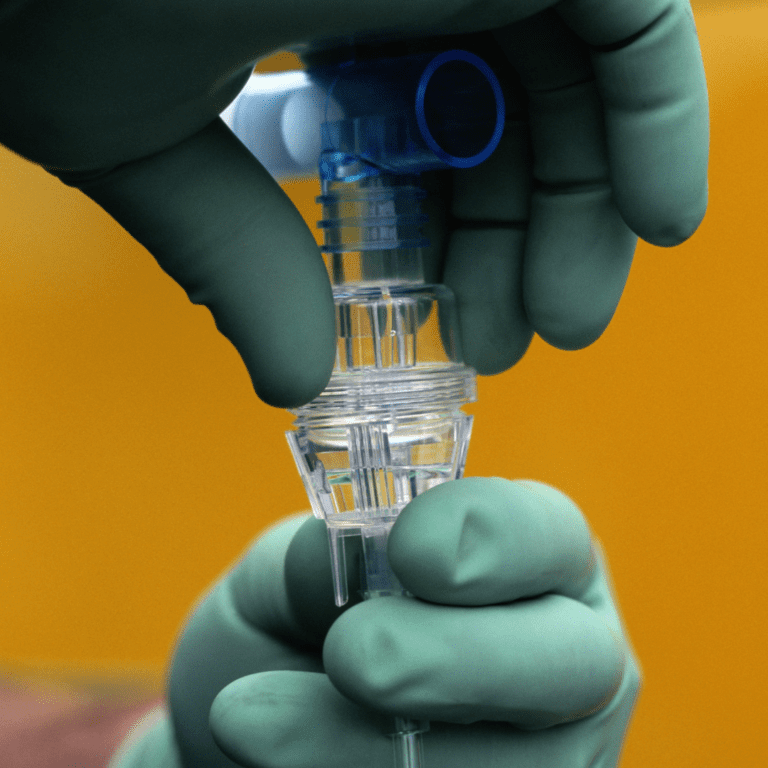

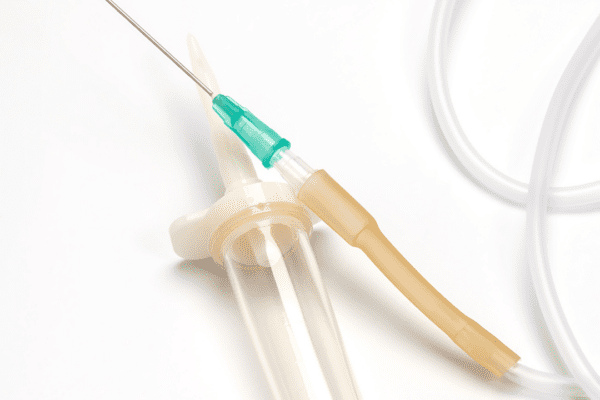

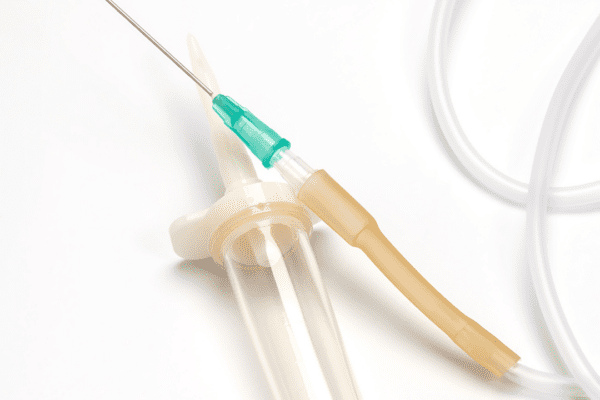

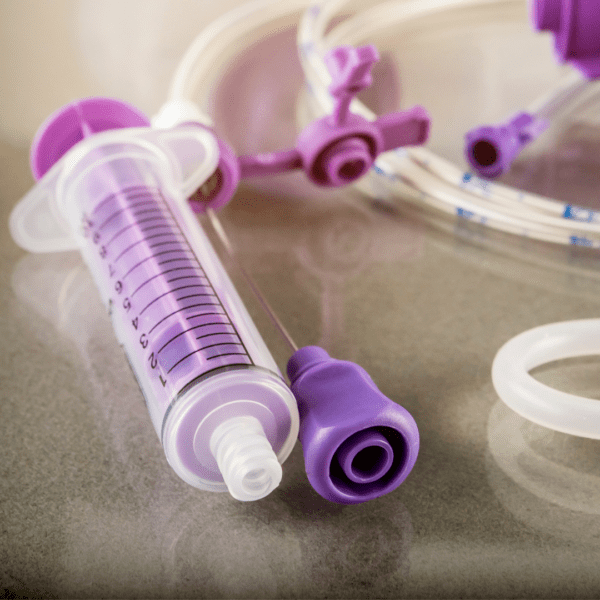

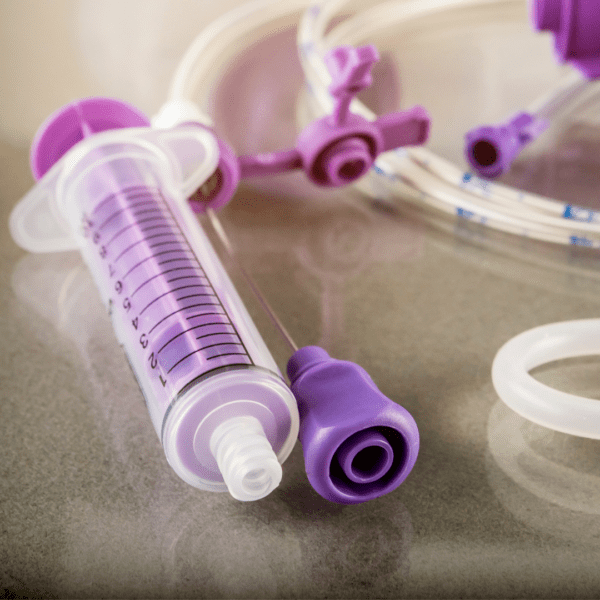

In patient care settings, such as hospital bedsides and outpatient clinics, small-bore connectors and connections are used to combine the different medical devices, components, and accessories of a gas or liquid delivery system. The connected parts include such things as tubing, syringes, fluid bags, gas lines, filters, backflow preventers and so on. In combination, these parts make up sub-assemblies and assemblies (1).

What is a Luer?

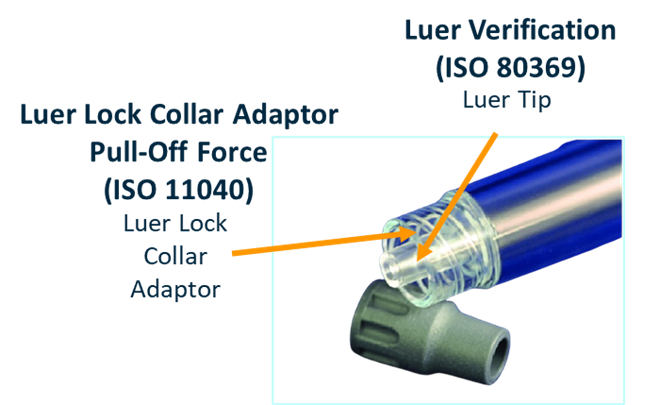

A luer is a standardised connection type based on a conical 6% (1:16) taper design, meaning the diameter increases by 1 unit for every 16 units of length. design. Luer fittings rely on this taper and the friction between the mating surfaces to provide quick, tight, leak-proof seals between male and female luers (1).

What is ISO 80369?

ISO 80369 is the series that covers small-bore connectors for liquids and gases in healthcare applications, ensuring compatibility and reducing the risk of misconnections.

Need help?

Let our team of experts help you understand what’s next!

Cormica's ISO 80369 service assesses these connector compliance:

ISO 80369-3 : Connectors for enteral applications

ISO 80369-5 : Connectors for limb-cuff applications

ISO 80369-6 : Connectors for neuroaxial applications

ISO 80369-7 : Connectors for intravascular or hypodermic applications

ISO 80369-20 : Small-bore connectors for liquids and gases in healthcare applications — Part 20: Common test methods. (This section includes measures for preventing incorrect connections.

Tests for the verification of connectivity include dimensional analysis and various leakage and stress tests according to each section of the standard

There are other areas under development for this standard:

ISO 80369-2 : Connectors for breathing systems and driving gases applications

ISO 80369-4 : Connectors for urethral and urinary applications

Why Choose Cormica for Your ISO 80369 Testing Needs?

We understand that ensuring compliance with ISO 80369 standards is critical to patient safety and device functionality. With our extensive expertise in small-bore connector testing, we offer a comprehensive range of services to help you meet these stringent standards. Here’s why you should choose us:

- Specialised Expertise: Our experienced engineers and scientists are leaders in ISO 80369 compliance testing, ensuring precise and reliable results that give you peace of mind.

- Fast Turnaround Times: We know time-to-market is crucial, so we offer efficient testing services without compromising quality, helping you meet tight deadlines.

- Customised Solutions: Whether you need testing for a single connector or a full range of products, we tailor our services to meet your unique needs, ensuring a personalised approach.

- Commitment to Safety and Compliance: Our testing services ensure your products meet global regulatory requirements, minimising the risk of misconnections and enhancing patient safety.

- Exceptional Support: From the initial enquiry to the final report, our team provides dedicated support at every stage of the process, offering expert guidance to help you navigate the complexities of ISO 80369 compliance.

Common Methods stated in the Standard, are as Follows;

- Ease of Assembly

- Air Leakage (Leakage by Pressure Decay)

- Resistance to Separation from Axial Load (Separation Force)

- Resistance to Separation from Unscrewing (Unscrewing Force)

- Stress Cracking followed by Positive Pressure Liquid Leakage

- Positive Pressure Liquid Leakage

- Sub Atmospheric Positive Pressure Air Leakage

- Resistance to Overriding

- Disconnection by Unscrewing

- Dimensional Requirements

Choosing The Component to Test with your Sample

Option 1 – Testing your devices port with the sub assembly your device will be connected to in real life application

Advantage – Reassurance your devices port will comply with the exact assembly it is planned to be mated with.

Disadvantage – Cannot confirm your devices port will have a leak proof seal with any standardised luer.

Option 2 – Testing your devices port with a reference connector.

Advantage – Calibrated regularly, steel material so there is minimal risk of materials reacting or degradation during testing.

Disadvantage – Specific references required for each test type as a result it cost more.

Option 3 – A sub-assembly that is already on the market.

Advantage – Allows for multiple samples to be tested on one occasion. This is beneficial for stress cracking tests, which require a 48-hour conditioning period. Testing multiple samples simultaneously reduces the test duration and costs.

Disadvantage – Cannot be calibrated.

ISO 80369 Testing Matrix Table

| Method | Standard | Acceptance Criteria | Reference Connector | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ISO 80369-3 Female (Fig C.1 Lock) | ISO 80369-3 Male (Fig C.2 Lock) | ISO 80369-3 Male (Fig C.3 Lock) | ISO 80369-6 Female (Fig C.4 Lock) | ISO 80369-6 Male (Fig C.5 Slip) | ISO 80369-7 Female (Fig C.1 Lock) | ISO 80369-7 Female (Fig C.3 Slip) | ISO 80369-7 Male (Fig C.5 Lock) | |||

| Air Leakage (Leakage by Pressure Decay) | (ISO 80369-20 Annex B) | The luer connector shall not leak by more than 0.005Pa·m3/s. | + | + | + | + | + | |||

| Positive Pressure Liquid Leakage | (ISO 80369-20 Annex C) | There must be no leakage of water sufficient to produce a falling drop of water. | + | + | + | + | + | |||

| Resistance to Separation from Axial Load | (ISO 80369-20 Annex F) | The fitting assembly must resist separation. | + | + | + | + | + | |||

| Resistance to Separation from Unscrewing | (ISO 80369-20 Annex G) | The fitting assembly must resist separation from unscrewing. | + | + | + | + | + | + | ||

| Stress Cracking Positive Pressure Liquid Leakage | (ISO 80369-20 Annex E) (ISO 80369-20 Annex C) |

There must be no leakage of water sufficient to produce a falling drop of water. | + | + | + | + | + | |||

| Sub Atmospheric Air Leakage | (ISO 80369-20 Annex D) | The luer connector shall not leak by more than 0.005Pa·m3/s. | + | + | + | + | + | |||

| Resistance to Overriding | (ISO 80369-20 Annex H) | The fitting assembly must not show evidence of overriding. | + | + | + | + | + | + | ||

| Disconnection by Unscrewing | (ISO 80369-20 Annex I) | Torque after completely detaching is recorded. | + | + | + | + | + | |||

| Non-Interconnectivity | ISO 80369-7 4.1 | Compare the fitting assembly with other connectors. | + | + | + | + | + | + | ||

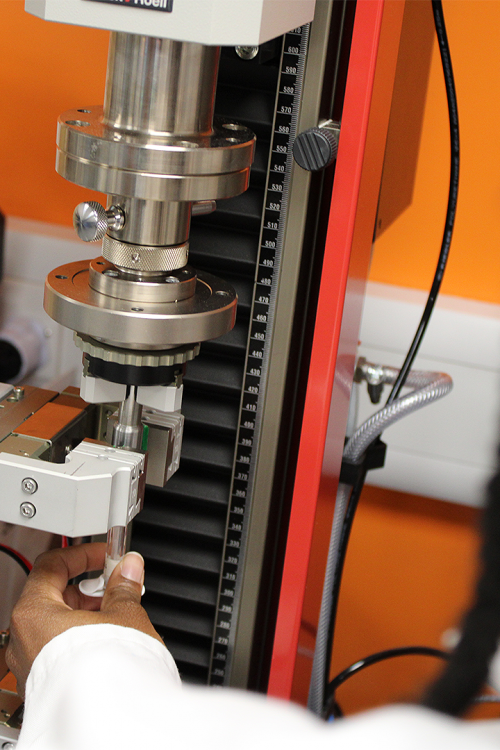

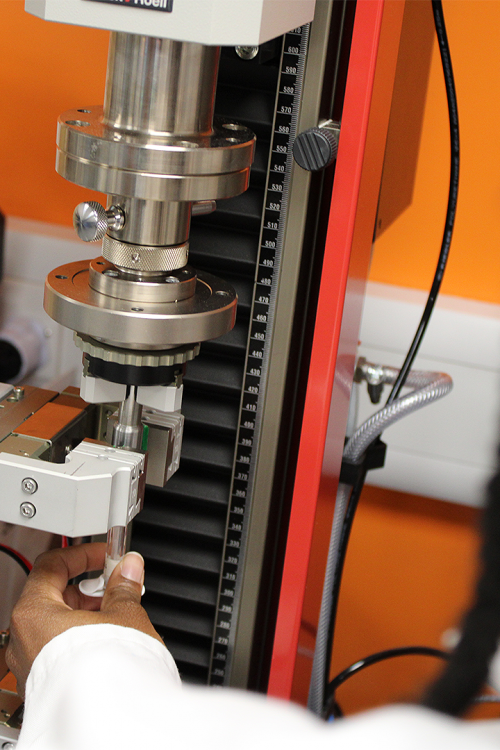

Due to the ISO 80369 standard outlining specific parameters (forces, torques, pressures) that need to be applied onto the sample, on site we have a CFR Part 11 compliant machine that can apply a torque simultaneously with axial forces, allowing us to mimic connecting and disconnecting the samples to carry out several of the methods in the ISO 80369 series.

Measuring dimensions is not a requirement.

Dimensions may be taken by CT X-Ray scanning or more traditional means such as digital calipers, profile projectors, or measuring microscopes or through gauging tests.

ISO 80369 Testing FAQ’s

How many ports need testing?

Please note that our quotes are based on the number of ports requiring testing. For example, if you commission stress cracking tests for 10 connectors and need two ports tested per connector, we will need to test 20 ports in total, which will extend the test period.

What will your sample be mated with?

This information helps us plan equipment availability, provide an accurate test duration, and determine which ends need to be checked for leaks.

Can you provide spare samples before testing begins?

Having spare samples in advance allows us to collaborate with our expert engineers to create any necessary custom test rigs for your samples.

Contact Us

References

- Industrial Specialties Mfg (2021) What is an ISO 80369-7 Compliant Luer? – The New Luer Standard. Available at: What is an ISO 80369–7 Compliant Luer? – The New Luer Standard | ISM (industrialspec.com) (Accessed: 25 June 2024)