Packaging Testing

Expert Packaging Testing and Validation Services

We recognise that the integrity of your product packaging is essential to ensuring safety, compliance, and performance throughout its lifecycle.

Our comprehensive packaging testing and packaging validation services, including machine validation, are designed to verify that your packaging meets the highest industry standards, providing the confidence you need to bring your medical devices, pharmaceuticals, and biotechnology products to market safely.

We can assist in evaluating your machine validation through testing of your Installation Qualification (IQ), Operational Qualification (OQ) and Performance Qualification (PQ) runs.

Our Packaging Testing and Validation Services Include

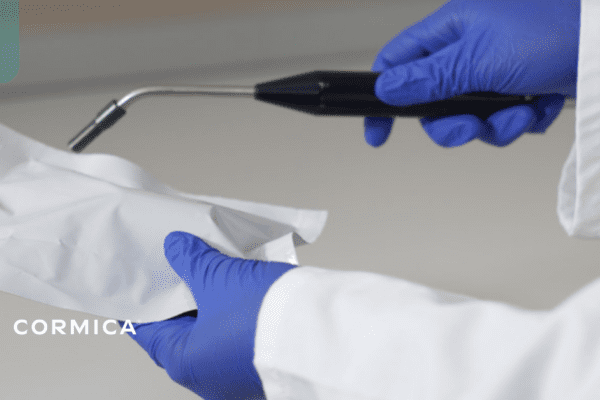

- Visual Inspection (ASTM F1886/F1886M): Ensuring packaging is free from defects that could compromise sterility.

- Peel Testing (ASTM F88/F88M): Validating the durability and reliability of flexible barrier seals (Seal Strength).

- Burst Testing (ASTM F1140/F2054): Assessing the resilience of package seals under pressure to confirm integrity (Seal Strength).

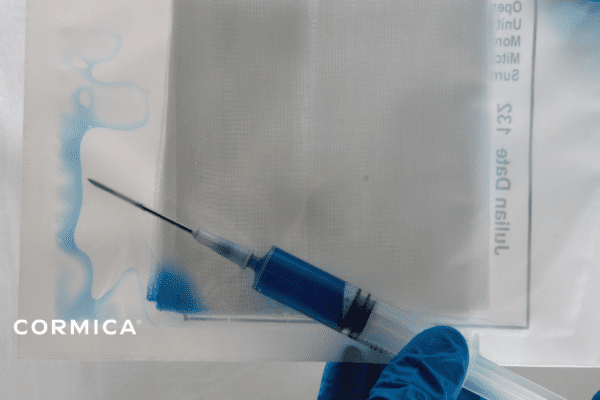

- Dye Penetration (ASTM F1929): Detecting potential seal leaks using dye penetration for porous medical packaging (Seal Integrity).

- Bubble Leak (ASTM F2096): Determination of gross leaks in packaging via internal pressurisation.

- Bubble Emission (ASTM D3078): Determination of gross leaks in flexible packaging containing a headspace gas.

- Leak Detection (ASTM F3039-15) Standard Test Method for Detecting Leaks in Nonporous Packaging or Flexible Barrier Materials by Dye Penetration

By utilising industry-leading standards, our packaging testing and validation services ensure your products are packaged securely, meet regulatory requirements, and arrive safely at their destination. Backed by Cormica’s dedication to ethical practices, continuous improvement, and teamwork, we help you bring products to market with confidence.

Trust Cormica for reliable packaging testing and validation services that safeguard patient safety and product efficacy.